- Home Page

- Company Profile

-

Our Products

- PCE

- Polycarboxylate super plasticizer

- Polycarboxylate Ether Superplasticiser

- poly carboxylic acid

- Polycarboxylate Solution

- Polycarboxylate Water Reducer

- Slump Retention Type Polycarboxylate Superplasticizer

- Polycarboxylic acid superplasticizer

- PCE polycarboxylate superplasticizer

- PCE polycarboxylate

- PCE polycarboxylate ether

- Polycarboxylate Superplasticizer

- concrete water reducing admixture

- Water Reducing Type Polycarboxylate Superplasticizer

- PCE Polymer

- SNF

- Water Reducing Agent

- SNF B

- sodium naphthalene sulfonate

- SNF C

- Poly Naphthalene Sulfonate Formaldehyde

- PNS A

- SNF A

- poly sodium naphthalene sulfonate

- SNF Powder

- Naphthalene Sulfonate Superplasticizer

- sodium naphthalene sulphonate formaldehyde

- Sodium Naphthalene Sulphonate

- Sodium naphthalene formaldehyde

- Concrete and Mortar Admixture

- Sodium Gluconate

- Sodium Naphthalene Sulfonate

- Polycarboxylate Ether Superplasticizer

- concrete admixture superplasticizer

- Concrete Superplasticizer

- concrete admixture polycarboxylic acid

- Cement additive polycarboxylates

- PCE Admixtures

- polycarboxylate liquid admixtures

- PCE Superplasticizer

- high range water reducing admixture

- concrete admixture polycarboxylates

- PolyCarboxylate Ether Polymer

- Polycarboxylate Ether

- Polycarboxylate Superplasticizer

- PCE

- Contact Us

Polycarboxylate Superplasticizer

500 USD ($)/Metric Ton

Product Details:

- Grade A

- Color Yellow

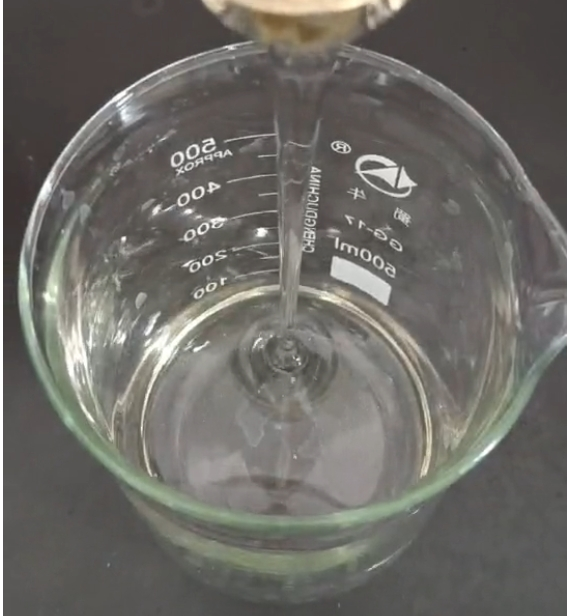

- Physical Form Liquid

- HS Code 382440

- Type Polycarboxylate Superplasticizer

- Purity 99%

- Application Industrial

- Click to View more

X

Polycarboxylate Superplasticizer Price And Quantity

- 1 Twenty-Foot Container

- 500 USD ($)/Metric Ton

Polycarboxylate Superplasticizer Product Specifications

- A

- Yellow

- 382440

- Liquid

- Polycarboxylate Superplasticizer

- 99%

- Industrial

- 8

Polycarboxylate Superplasticizer Trade Information

- QINGDAO, CHINA

- Paypal, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- 5000 Twenty-Foot Container Per Month

- 7 Days

- Yes

- Contact us for information regarding our sample policy

- 1000L IBC TANK; 20000 FLEXIBLE BAG

- All India

- ISO, REACH, CE

Product Description

Polycarboxylate superplasticizer is a new generation of polycarboxylic acid series highperformance water reducing agent formed by free radical polymerization of polyoxyethylene ether macromers unsaturated acids and sulfonic acid monomers The product has a high water reduction rate and low slump loss performance ensuring excellent workability high strength and excellent durability of concrete It can be widely used in pumped concrete ultra fluid self compacting highstrength highperformance concrete and commercial concrete

Technical Principles

After adding a water reducing agent to concrete the hydrophobic group of the water reducing agent is directional adsorbed on the surface of cement particles while the hydrophilic group points to the aqueous solution forming a singlemolecule or multimolecule layer adsorption membrane Due to the directional adsorption of surfactant the surface of cement particles carries the same sign of charge Therefore under the action of isotropic repulsion not only can the cement water system be in a relatively stable suspended state but also the flocculent structure formed in the early stage of water addition can be dispersed and disintegrated thereby releasing the water within the flocculent structure and achieving the goal of reducing water content

Product Characteristics

Outstanding comprehensive performance The product has a high water reduction rate up to 35water reduction rate and a low slump loss rate which can effectively improve the working performance of concrete enhance its strength and durability

Good workability of concrete Fresh concrete has good workability no segregation no bleeding good cohesion moderate air content and is suitable for pumping

Concrete has high hardening and durability performance

Concrete has high strength at all ages good volume stability outstanding impermeability freezethaw resistance corrosion resistance and carbonation resistance

Wide adaptability It has wide adaptability to Portland cement ordinary Portland cement slag silicate fly ash cement volcanic ash cement and various admixtures

Green and environmentally friendly The raw materials used are nontoxic and harmless and there are no three wastes generated during the production process

Usage Method

When using this product in practice it should be diluted and compounded with water as needed before use

The commonly used dosage is 0612 calculated based on the total amount of cementitious materials and the optimal dosage should be determined through experiments based on the engineering materials and characteristics

Water reducing agents can be dissolved in water or added separately to concrete mixers

It can be used in combination with lignosulfonate water reducing agents and various retarders

Our company provides a complete set of composite usage technology which can provide training for users If there are any difficult problems engineers can come to our doorstep for guidance

Applicable Scope

Suitable for preparing early strength concrete slow setting concrete Prefabricated concrete castinplace concrete high flow concrete self compacting concrete mass concrete highperformance concrete soil and plain concrete various industrial and civil buildings premixed and castinplace concrete especially suitable for lowgrade goods concrete

Widely used in highspeed railways nuclear power water conservancy and hydropower projects subways large bridges highways ports and docks national largescale and key projects

Suitable for various types of industrial and commercial construction and commercial concrete mixing stations

Packaging Storage

This product is liquid sealed in 200KG and 1000KG barrels During storage it is necessary to prevent leakage exposure to sunlight and high temperatures

The shelf life is two years and must be inspect and qualified before use

This product is an alkali free liquid nontoxic noncorrosive and non polluting to the environment but t is not edible

Index of Water Reducing Agent

Item

lndex

Actual quality

Appearance

Light yellow transparent liquid

Density gcm3

110250015

11025

PH Value 68

7

Solid content

501

50

Alkali content

100

024

Chloride ion content

0200

006

Sodium sulfate content

1000

122

Cement paste fluidity mm

240

240

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free